STI SP001: Inspection of Above Ground Storage Tanks

- The Steel Tank Institute’s SP001 Inspection Standard deals directly with above ground storage tanks (ASTs), up to 30 feet in diameter and 50 foot tall. However, this standard is most commonly utilized in the inspection of carbon steel shop fabricated tanks ranging from 1,000 gallons to 30,000 gallons. These parameters cover a great deal of tanks within the industry. Because of this. STI SP001 is a highly utilized inspection standard for ASTs developed to provide an alternative inspection standard to API 653. The STI SP001 standard allows for a less stringent and more relevant inspection procedure to be followed when inspecting Shop Fabricated tanks, small field erected tanks not built to API 12C or 650, and portable containers.

STI SP001 Inspectors

To properly interpret the standard, carefully carryout inspections and provide industry related reports, our inspectors must meet certain knowledge and experience requirements to be able to apply to become a certified STI SP001 Inspector through the Steel Tank Institute. Once approved, they must pass proctored examinations to gain entry into the industry as a certified inspector, something we pride ourselves on and hold with great integrity. Recertification must take place every 5 years in order to stay up to date with the latest industry standards and practices.

STI SP001 Inspection Frequency

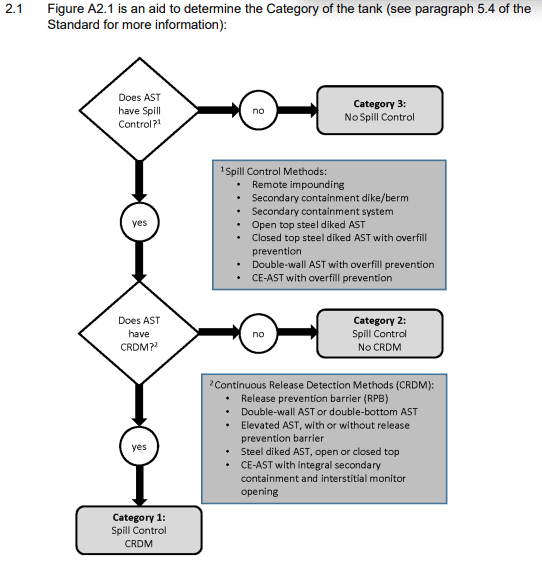

Inspection Frequency is determined by the type of product being stored, the volume of product stored and the tank’s ability to withstand the probable error that could occur. To determine the inspection intervals, tanks are broken down into three different categories. Classes range from #1 to #3 where class #3 holds the greatest risk potential. The greater the risk potential, the greater the inspection frequency:

Category 1: ASTs with Spill Control and CRDM

Category 2: ASTS with Spill Control, and without CRDM

Category 3: ASTs without Spill Control

P = Period Inspection (Monthly)

E = External Inspection

L = Leak Test

I = Internal Inspection

Pressure Leak Testing for STI Tanks

A popular inspection technique for small ASTs and USTs is to Performing a Pressure Leak Test. This type of test must be performed very carefully as it forces air into the tank causing pressure to build within. This contained pressure (Psig) allows for an inspector to determine if a tank has a small leak that could potentially turn into a large leak. A leak test is performed once a tank is empty of product, pressurized to 3-5 PSI and closely montored for minute drops in pressure. It requires certified guages capable of detecting drops in pressure as small as 1/10 of a PSI, as well as, a collection of fittings, valves, and regulators for the specific tank and its nozzle requirements.

Pro-Tip: API 570

For Process Piping that is in intermittent service, the inspection interval may be based off of the number of years of working service, rather than calendar years, provided that when sitting idle, the piping is:

- – Absent of all process fluids

- – Purged and sealed free from all corrosive catalysts, such as Inert gas. (API 570, 6.3.3)